|

| |

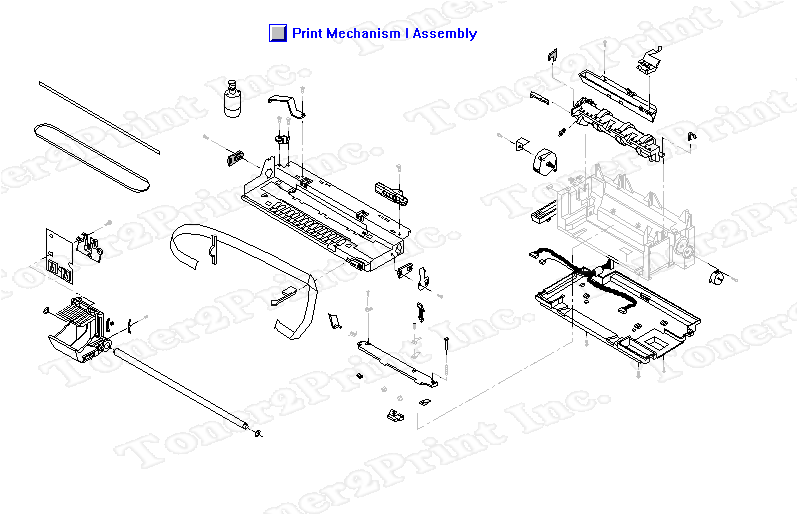

C4531-60015 is represented by #26 in the diagram below.

- 1

- 1 C4531-69813 - Complete mechanism - Includes mechanical carriage movement, paper picking, and service station operations - Used to replace all three types of print mechanisms

- 6

- 6 C2145-40019 - Pressure plate lifter - Also known as lifter shaft or paper lifter

- 7

- 7 C2145-20007 - Carriage rod - Shaft that the carriage assembly rides on

- 11

- 11 C2145-40023 - Kicker - Restacks the paper in the paper input tray after the top sheet is removed

- 14

- 14 C4531-60129 - Base assembly - Bottom cover with four rubber feet

- 15

- 15 C2145-40020 - Lever arm - Provides linkage between the pivot assembly and the pressure plate lifter

- 16

- 16 C4531-60016 - Service station motor - Drives service station assembly

- 18

- 18 C4531-40011 - Carriage flex cable clip - Holds the flex cable

- 19

- 19 C2145-00018 - Encoder spring - Provides tension for the encoder strip and grounds the carriage rod to the carriage plate

- 20

- 20 C2145-40059 - Eccentric bushing - Used to adjust pen-to-paper spacing (2 used)

- 21

- 21 C4555-40063 - Chassis clamp - Retains chassis in the base assembly

- 22

- 22 C4531-80010 - Head drive flex cable - 41.9cm (16.5in) long

- 23

- 23 C4531-67803 - Head drive PCA - Has temperature and optical sensors - Drives the print cartridge

- 24

- 24 C4531-40009 - Belt attachment - Anchors drive belt to carriage

- 25

- 25 C4555-60068 - Turnaround assembly - Holds belt tension components in place

- 26

- 26 C4531-60015 - Paper motor - Drives paper through printer - Has diagonal teeth (Helical) on drive gear

- 28

- 28 C2145-67804 - Pivot - Large plastic item which contains the pickup rollers

- 30

- 30 C2145-40101 - Right pivot clamp (Right Z-STOP) - Holds the right end of the pivot assembly in place

- 31

- 31 C2145-00046 - Pivot spring - Provides tension for the pivot

- 32

- 32 C2145-40059 - Eccentric bushing - Used to adjust pen-to-paper spacing (2 used)

- 33

- 33 C4555-60067 - Carriage belt idler wheel assembly - Includes: idler mount, pulley, ball bearing and idler axle

- 34

- 34 C2145-40058 - Drive belt - For the print mechanism carriage assembly

- 35

- 35 C2145-80016 - Encoder strip - Carriage position sensor reference

- 36

- 36 C4555-40066 - Clutch actuator arm - Used to engage the pivot gears

- 39

- 39 C2145-00042 - Encoder stiffener - Prevents oscillation of encoder strip

- 40

- 40 C2145-40117 - Left pivot clamp (Left Z-STOP) - Holds the left end of the pivot assembly in place

- 41

- 41 C4602-60022 - Carriage motor - Provides power for carriage belt

1

C4531-69813

Print Mechanism

Complete mechanism - Includes mechanical carriage movement, paper picking, and service station operations - Used to replace all three types of print mechanisms

6

C2145-40019

Lifter

Pressure plate lifter - Also known as lifter shaft or paper lifter

7

C2145-20007

Rod

Carriage rod - Shaft that the carriage assembly rides on

11

C2145-40023

Kicker

Kicker - Restacks the paper in the paper input tray after the top sheet is removed

14

C4531-60129

Base

Base assembly - Bottom cover with four rubber feet

15

C2145-40020

Arm

Lever arm - Provides linkage between the pivot assembly and the pressure plate lifter

16

C4531-60016

Motor

Service station motor - Drives service station assembly

18

C4531-40011

Clip

Carriage flex cable clip - Holds the flex cable

19

C2145-00018

Spring

Encoder spring - Provides tension for the encoder strip and grounds the carriage rod to the carriage plate

20

C2145-40059

Adjuster

Eccentric bushing - Used to adjust pen-to-paper spacing (2 used)

21

C4555-40063

Clamp

Chassis clamp - Retains chassis in the base assembly

22

C4531-80010

Cable

Head drive flex cable - 41.9cm (16.5in) long

23

C4531-67803

PC Board

Head drive PCA - Has temperature and optical sensors - Drives the print cartridge

24

C4531-40009

Clamp

Belt attachment - Anchors drive belt to carriage

25

C4555-60068

Turnaround Assembly

Turnaround assembly - Holds belt tension components in place

26

C4531-60015

Motor

Paper motor - Drives paper through printer - Has diagonal teeth (Helical) on drive gear

28

C2145-67804

Pivot

Pivot - Large plastic item which contains the pickup rollers

30

C2145-40101

Clamp

Right pivot clamp (Right Z-STOP) - Holds the right end of the pivot assembly in place

31

C2145-00046

Spring

Pivot spring - Provides tension for the pivot

32

C2145-40059

Adjuster

Eccentric bushing - Used to adjust pen-to-paper spacing (2 used)

33

C4555-60067

Idler

Carriage belt idler wheel assembly - Includes: idler mount, pulley, ball bearing and idler axle

34

C2145-40058

Belt

Drive belt - For the print mechanism carriage assembly

35

C2145-80016

Strip

Encoder strip - Carriage position sensor reference

36

C4555-40066

Arm

Clutch actuator arm - Used to engage the pivot gears

39

C2145-00042

Stiffener

Encoder stiffener - Prevents oscillation of encoder strip

40

C2145-40117

Clamp

Left pivot clamp (Left Z-STOP) - Holds the left end of the pivot assembly in place

41

C4602-60022

Shield

Carriage motor - Provides power for carriage belt

|

|